Multimaterial 3D printer builds working motor from scratch in hours

MIT researchers have built a 3D-printing platform that can fabricate fully functional electric machines in a single process, potentially allowing factories to produce replacement motors on-site within hours.

The system uses multimaterial extrusion to print complex devices made of conductive, magnetic, and structural materials without the need for specialized manufacturing facilities.

In a demonstration, the team printed a working electric linear motor in about three hours.

Electric machines are typically manufactured in centralized facilities using multiple fabrication steps and specialized equipment.

When a motor fails on a factory floor, replacing it often requires ordering parts from far away, leading to downtime and added costs.

The MIT team aims to change that by making it possible to print such devices locally, using a single integrated platform that can handle different material types in one build.

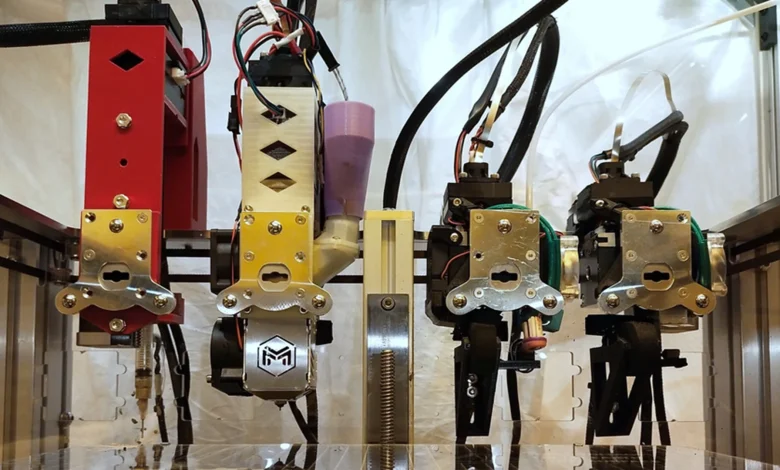

To achieve this, the researchers modified an existing extrusion-based 3D printer. They added four separate extruders, each designed to process a different type of feedstock. Some materials are deposited as melted filaments, while others, such as conductive inks, require pressure-driven systems.

Printing machines in one step

“There were significant engineering challenges. We had to figure out how to marry together many different expressions of the same printing method — extrusion — seamlessly into one platform,” says Luis Fernando Velásquez-García, a principal research scientist in MIT’s Microsystems Technology Laboratories and senior author of the study.

The system incorporates strategically placed sensors and a new control framework to ensure that each tool is positioned precisely. Even small misalignments between layers can compromise performance in electric machines, so accuracy was critical.

The team focused on printing a linear motor, which produces straight-line motion and is commonly used in robotics, optical systems, and conveyor belts.

The motor was printed using five different materials and required only one post-processing step: magnetizing the hard magnetic components.

The researchers estimate the material cost of the printed motor at roughly 50 cents. Performance tests showed that it generated several times more actuation than a common type of linear engine that relies on complex hydraulic amplifiers.

Rethinking electronics production

The researchers see the motor as a proof of concept rather than the final goal. The broader vision is distributed manufacturing of complex electronic and electromechanical systems, reducing reliance on global supply chains.

“This is a great feat, but it is just the beginning. We have an opportunity to fundamentally change the way things are made by making hardware onsite in one step, rather than relying on a global supply chain. With this demonstration, we’ve shown that this is feasible,” says Velásquez-García.

In the future, the team plans to integrate the magnetization step directly into the printing process and demonstrate fully 3D-printed rotary motors.

They also intend to expand the number of tools on the platform to enable the monolithic fabrication of more advanced electronic devices.

“Even though we are excited by this engine and its performance, we are equally inspired because this is just an example of so many other things to come that could dramatically change how electronics are manufactured,” says Velásquez-García.