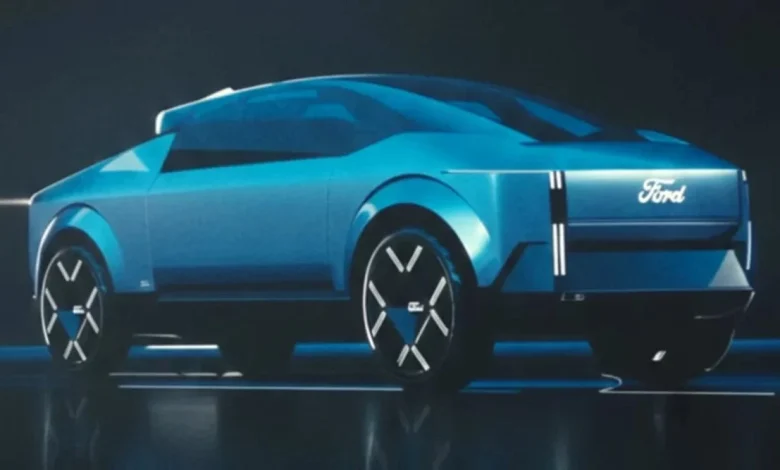

Ford’s New $30K EV Truck is a Tesla Cybertruck Underneath

February 20, 2026

By Karan Singh

When Tesla launched the Cybertruck, its brutalist stainless-steel exterior dominated the headlines. It looked and felt – and still does today – like something otherworldly. But beneath the polarizing design lies a trove of massive, high-risk manufacturing innovations pioneered by Tesla.

Now, as Ford gears up to launch a highly anticipated $30,000 mid-size electric truck in 2027, it is becoming abundantly clear that the engineers at the Blue Oval have been taking meticulous notes.

In fact, Ford didn’t just copy Tesla’s homework – they hired the engineers who wrote it.

Learning the Tricks

Led by Doug Field and Alan Clarke, both former high-ranking Tesla executives with over a decade of experience building Tesla’s underlying architecture, Ford’s new skunkworks team has been hard at work developing their new Universal Electric Vehicle (UEV) platform.

By adopting the exact same first-principles engineering that Tesla used on the Cybertruck, Ford has completely ripped up its old legacy playbook. This is the first time that a legacy OEM has decided to take such drastic steps in adopting from Tesla’s playbook.

Shifting to 48V and Zonal Architecture

For decades, the automotive industry has relied on standard 12-volt electrical systems. The Cybertruck was the first vehicle to break that mold by shifting to a fully 48-volt architecture. In fact, Elon Musk open-sourced a how-to pamphlet that was sent out to legacy OEM CEOs to encourage their adoption of the new, more efficient system. Jim Farley was one of the first to receive it, and he publicly thanked Elon Musk back in 2023.

They weren’t joking. We received the document today, dated Dec. 5th. Thanks, @ElonMusk. Great for the industry! https://t.co/DkLaHA84CY

— Jim Farley (@jimfarley98) December 7, 2023

Ford’s new UEV platform fully embraces this 48-volt system. Because higher voltage means less current is required to deliver the same power, that means Ford can use significantly thinner wires. Paired with a new zonal architecture similar to the one that Tesla already uses and Rivian recently implemented, it consolidates dozens of third-party controllers into just five Ford-designed CPUs.

The results from this optimization are staggeringly efficient. Ford claims the new wiring harness for this mid-size truck will be over 4,000 feet shorter and 22 pounds lighter than the one used in the Mustang Mach-E – a vehicle of comparable body size.

48V Accessories May Become Standard

This is a drastic shift for the accessory industry. Today, it is a challenge to find electrical accessories that are compatible with the Cybertruck, and you often have to down-step the voltage or use esoteric tricks with lead-acid batteries to power things like winches, unless they are made specifically for it.

With a large OEM like Ford leaning into 48V, we will likely see a lot of compatible, first- and third-party 48-volt accessories, which will eventually become compatible with the Cybertruck.

From 146 to 2: The Magic of Gigacastings

Tesla revolutionized automotive manufacturing by using massive high-pressure die-casting machines, known as Gigapresses, to cast entire sections of the Model Y and Cybertruck underbodies in a single piece, eliminating hundreds of welds and the work of hundreds of feet of robots on the assembly line.

Ford is bringing this exact process to the UEV platform under the new name “Unicasting”. To put the efficiency gains into perspective, the front and rear structures of the current gas-powered Ford Maverick comprise 146 stamped parts. On the new UEV truck, those parts have been condensed into just two massive aluminum castings.

Structural LFP Core

To bridge those two massive front and rear unicastings together, Ford is taking another page from Tesla’s playbook: the structural battery pack.

Rather than building a heavy steel frame and bolting the battery inside, the new UEV platform uses the battery pack itself as the foundational floor structure of the vehicle.

To keep costs low and hit that $30,000 starting price, Ford is using LFP (lithium-iron phosphate) batteries in this platform. While they’re less energy dense and have smaller temperature sweet-spots than standard nickel-based batteries, they are between 20-30% cheaper to produce.

By following an aggressive process to optimize the aerodynamics and slimming the side mirrors by 20% using a single motor, Ford is expecting to squeeze over 300 miles of range from this small and cheap LFP pack.

The End of the Line

Perhaps the most radical change is how the truck will actually be put together. Henry Ford famously invented the moving assembly line over a century ago, but Ford might be the first legacy OEM to begin putting it aside for a mirror of Tesla’s unboxed strategy – the assembly tree method.

Instead of a vehicle frame slowly moving down a single mile-long line as workers bolt parts onto it, the Ford truck will be built in three completely independent sub-assemblies (the front casting, the rear casting, and the structural battery core). The seats, center console, and carpeting are bolted directly to the open battery pack before the front and rear sections are finally merged together.

This vastly improves worker ergonomics and shrinks the factory footprint, allowing Ford to build the truck 15% faster with 40% fewer workstations.

Wrapping It Up

While the Cybertruck used gigacasting and 48-volt architecture to build a premium, six-figure halo vehicle, Ford’s genius lies in using those exact same innovations to democratize the EV.

If Doug Field, Alan Clarke, and the rest of the Ford team can successfully execute this Tesla-inspired blueprint at scale, the $30,000 mid-size truck will be a massive win for Ford – and for Cybertruck owners as all these parts and techniques become standardized throughout the industry.

Subscribe to our newsletter to stay up to date on the latest Tesla news, upcoming features and software updates.

February 20, 2026

By Nehal Malik

Tesla is playing a high-stakes game of “beat the clock” with its latest release. This week, the automaker quietly launched a new Dual Motor All-Wheel Drive (AWD) Cybertruck starting at just $59,990 — far and away the most affordable version of the electric truck to date, but not for long.

The new trim feels like a direct apology for the short-lived Rear-Wheel Drive (RWD) Cybertruck that Tesla launched and then quickly killed off last year. While that $69,990 RWD model was widely panned for being “gutted” — missing essentials like the powered tonneau cover and bed outlets — the new $59,990 AWD version actually keeps the features that matter.

A Real Work Truck

By trimming luxury instead of utility, Tesla has created what the base model should have been from the start. This new version retains the powered tonneau cover and the vital Powershare capability, including the 120V and 240V outlets in the bed. For contractors or anyone at a job site, having a massive battery that can actually power heavy-duty tools is a must, and Tesla finally delivered.

To hit the sub-$60k price point, the company did have to make some cuts. The most notable is the swap from adaptive air suspension to a coil spring setup with adaptive damping. While you lose the ability to raise and lower the ride height, the truck maintains its impressive 4.1-second 0-60 mph time and an EPA-estimated 325 miles of range, matching the more expensive trims.

Interior Trade-offs

Inside, the tactical grey textile interior replaces the premium vegan leather found on higher-end variants, which actually makes it easier to clean if you’re getting in with muddy work boots. However, the $20,000 savings compared to the Premium (formerly Long Range) AWD trim means losing the 15-speaker audio system (it’s down to seven) and the 9.4-inch rear entertainment display. Passengers in the back also lose their heated seats, and the front seats are no longer ventilated.

The 10-Day Countdown

The catch? This price isn’t here to stay. Tesla CEO Elon Musk took to X to confirm that the $59,990 price tag is “only for the next 10 days.” This limited-time window has set off a wave of speculation about where the price will land once the clock runs out.

Only for the next 10 days https://t.co/82JnvZQGh2

— Elon Musk (@elonmusk) February 20, 2026

Given that the next tier up, the Premium AWD, sits at $79,990, it’s unlikely the base model will stay this cheap for long. Tesla could potentially hike it by $10,000 to match the original $69,990 price of the failed RWD model, or perhaps a smaller $5,000 bump to keep it just under that “psychological” $70,000 barrier.

If you’ve been waiting for a Cybertruck that actually makes sense as a utility vehicle, you have just over a week left to pull the trigger before the price goes up. Just how much it’ll rise remains to be seen.

February 20, 2026

By Nehal Malik

While EV sales might be hitting a bit of a speed bump lately, the people who actually own them have never been happier. According to the JD Power 2026 U.S. Electric Vehicle Experience (EVX) Ownership Study, owner satisfaction has climbed to an all-time high, with Tesla leading the charge.

The study, which is now in its sixth year, found that battery electric vehicle (BEV) owners are enjoying their cars more than ever. In fact, a staggering 96% of new owners say they would consider buying another EV for their next vehicle. Brent Gruber, executive director of the EV practice at JD Power, noted that while market share has dipped since federal tax credits ended in late 2025, that hasn’t stopped the positive vibes. “Improvements in battery technology, charging infrastructure and overall vehicle performance have driven customer satisfaction to its highest level ever,” Gruber said.

Tesla Dominates the Top Spots

If you’re looking for the happiest drivers on the road, look no further than the Tesla Model 3. It ranked highest overall in the study with a score of 804 out of 1,000, followed closely by its bigger sibling, the Tesla Model Y, which took second place with a score of 797.

This is just the latest win for the Model 3, which recently also grabbed Edmunds’ Top Rated Electric Car award for the second year running. It’s a testament to the car’s staying power, especially with the introduction of the new Model 3 Standard trim. This new entry-level version brings the same high-end tech and reliability that owners love to Tesla’s most affordable price point yet. Meanwhile, the Model Y continues to hold its own, having recently been named the best electric vehicle of 2026 by Consumer Reports.

Better Charging, Better Quality

One of the biggest surprises in the study was the massive jump in public charging satisfaction. For mass-market EV owners, satisfaction scores surged by 115 points year-over-year to 511, while premium owners reached 652. A big part of that is thanks to the opening of the Tesla Supercharger network to other brands, which has made finding a reliable plug much less stressful for everyone.

Premium EVs are also seeing major quality gains, with fewer reports of interior squeaks, rattles, or issues with driver assistance systems. Tesla has historically been teased for its interior build quality, but owners agree that it’s on the rise. On average, premium BEV owners reported only 75 problems per 100 vehicles, the best result in the study’s history.

BEVs vs. PHEVs

The study also highlighted a growing gap between pure electric vehicles (BEVs) and plug-in hybrids (PHEVs). While PHEVs are a great “gateway” for people not ready to go full electric, owners are significantly more satisfied with the cost of ownership in a pure BEV. Without the need for oil changes and traditional engine maintenance, BEVs are simply proving to be the more sensible long-term choice for most drivers.

With charging infrastructure finally catching up to the cars and vehicle quality hitting new records, the future for EVs looks bright — even if the sales charts are currently a little flat.